All uploaded files are strictly confidential.

All uploaded files are strictly confidential.

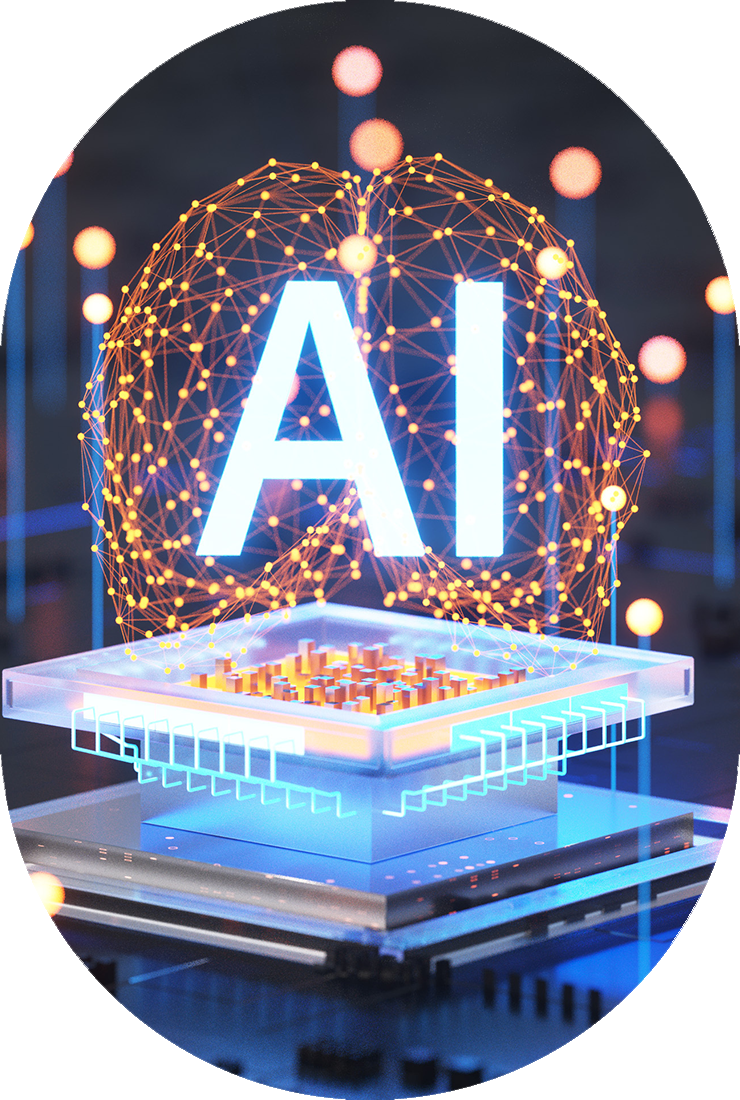

AI-Powered Flexible Manufacturing

Get Instant, Accurate Quotes

3D printing & CNC machining for rapid prototyping and small-batch production.

AI-powered instant quotes, online ordering, and secure workflows to cut costs and boost efficiency.

中文(中国)

中文(中国)