Applicable Scenarios of CNC Machining

Characteristics of CNC Machining

Machining Services

CNC Turning

3-axis, 4-axis, and full 5-axis machining

CNC Drilling

3-axis, 4-axis, and full 5-axis machining

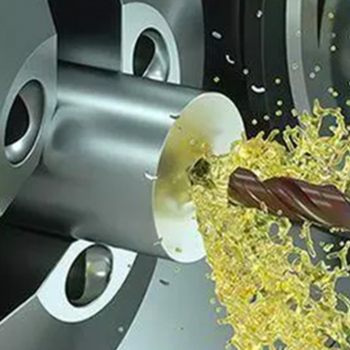

CNC Milling

3-axis, 4-axis, and full 5-axis machining

Material Processing

| Aluminum Alloy | Aluminum Alloy 6061 | Aluminum Alloy 5052 | Aluminum Alloy 2A12 | Aluminum Alloy 7075 | - | - | - | - |

| Stainless Steel | Stainless Steel 303 | Stainless Steel 304 | Stainless Steel 316 | Stainless Steel 316L | Stainless Steel 420 | Stainless Steel 430 | Stainless Steel 17-4PH | Stainless Steel 301 |

| Stainless Steel 321 | - | - | - | - | - | - | - | |

| Alloy Steel | Q235 (A3 Steel) | 45 Steel | Cr12 | 3Cr13 | GCr15 | 40Cr | Spring Steel 65Mn | Mold Steel SKD11 |

| Copper Alloy | Brass H59 | Brass H62 | Copper T2 | Oxygen-Free Copper TU2 | Tin Bronze QSn-6-6-3 | Beryllium Copper C17200 | - | - |

| Other Alloys | Electrical Pure Iron DT4C | Electrical Pure Iron DT4E | Titanium Alloy TC4 | Magnesium Alloy AZ91D | - | - | - | - |

| Plastics | Engineering Plastic ABS | Polytetrafluoroethylene PTFE | Delrin POM | Phenolic Board | Acrylic PMMA | Polypropylene PP | Polyphenylene Sulfide PPS | Polyurethane PU (Loctite Glue) |

| Polyvinyl Chloride PVC | Epoxy Board FR4 | High-Density Polyethylene HDPE | Low-Density Polyethylene LDPE | Nylon PA6 | Nylon PA66 | Polycarbonate PC | Polyetheretherketone PEEK | |

| Special Materials and Others | Carbon Fiber Board | Graphite | - | - | - | - | - | - |

What is CNC Machining?

CNC machining, short for Computer Numerical Control machining, refers to the control of machines by a set of commands issued by a controller. The commands issued by the controller are typically in the form of a list of coordinates, known as G-code. Any machine controlled by such codes can be referred to as a CNC machine, including milling machines, lathes, and even plasma cutters.

The movement of CNC machines can be defined by their axes, including the X-axis, Y-axis, and Z-axis, with more advanced machines also incorporating the A-axis, B-axis, and C-axis. The X-axis, Y-axis, and Z-axis represent the primary Cartesian vectors, while the A-axis, B-axis, and C-axis represent rotational axes. CNC machines typically utilize up to 5 axes.